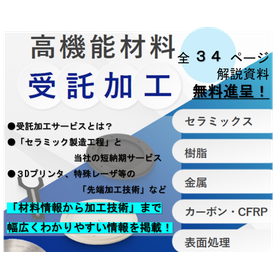

High-performance material contract processing services <Free handbook with processing examples>

We have created a guidebook for our contract processing services. It includes reasons for achieving "ceramics in as little as 2 weeks" and numerous other processing examples!

Narasaki Industries provides contract processing services that accommodate not only ceramics but also engineering plastics, metals, carbon/CFRP, and glass processing, as well as surface treatments such as coating and precision cleaning. This document explains the reasons why we can offer our specialty "short lead time ceramic processing service" in an easy-to-understand manner, covering: - The ceramics manufacturing process - Why we can respond to short lead times Additionally, we introduce advanced technologies such as "water laser processing technology," which differs from conventional CO2 and fiber thermal lasers, and "ceramics 3D printer technology," which enables the molding of hollow, lattice, and complex structures, along with processing examples. We also present various types and characteristics of "surface treatment technologies" and their processes. <For those with the following concerns> ◎ Looking for a processing partner for ceramics or special materials ◎ Need support for small quantities and short lead times ◎ Want to consult comprehensively from material selection to processing proposals *Please take this opportunity to obtain the handbook. You can view it immediately by downloading the catalog.

- Company:ナラサキ産業 メカトロソリューション部 機能材料課

- Price:Other

![Ceramics Processing [Special Materials Processing Achievements]](https://image.mono.ipros.com/public/product/image/e16/2000104971/IPROS4105057376362913163.JPG?w=280&h=280)

![[Parts Processing Example] Ceramics Wire Processing × Tapping Processing](https://image.mono.ipros.com/public/product/image/1bc/2000339933/IPROS6248519678479381989.jpg?w=280&h=280)

![[Product Example] Ceramics, Ferrites, Magnetic Material Processing](https://image.mono.ipros.com/public/product/image/cab/2001216578/IPROS28957687202446660853.png?w=280&h=280)